Maintenance Management PATRIOT® CMMS

PATRIOT® 3.0 Maintenance Management belongs to the group of systems known as CMMS (Computerized Maintenance Management Systems) or EAMS (Enterprise Asset Management Systems). It supports the restoration of objects using all maintenance strategies: from CORRECTIVE, PREVENTIVE to advanced DIAGNOSTIC and PREDICTIVE maintenance.

Corrective

Post malfunction

Preventive

Periodic

Diagnostic

SCADA

Predictive

Evaluation of parameters

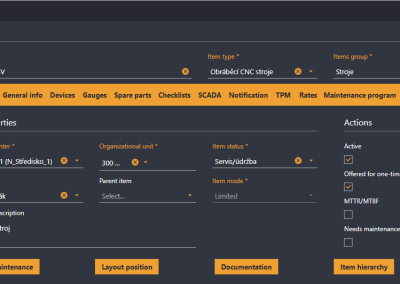

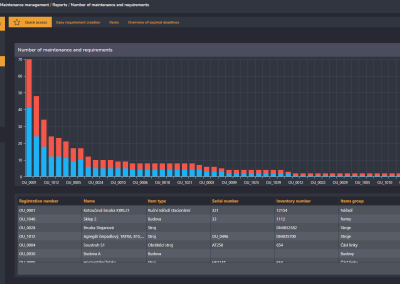

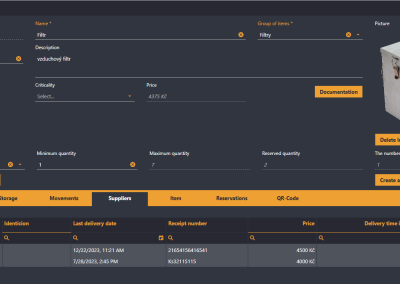

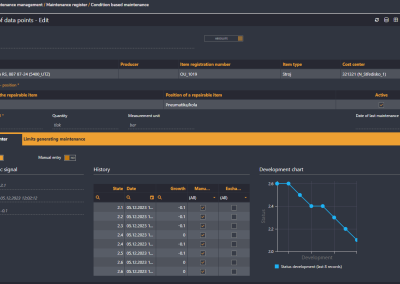

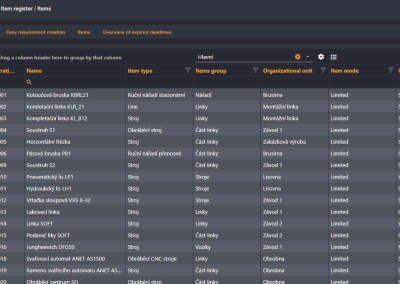

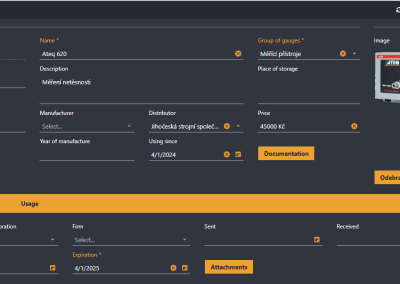

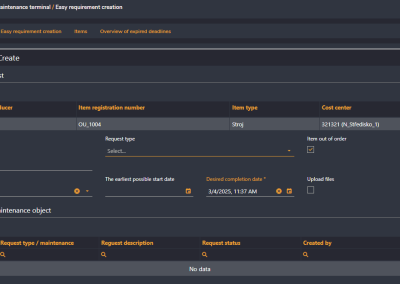

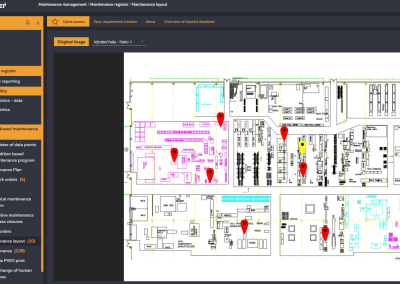

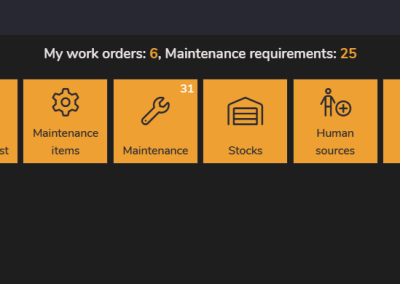

Sample screens

Maintenance management

PATRIOT® 3.0 Maintenance Management belongs to the group of systems known as CMMS (Computerized Maintenance Management Systems) or EAMS (Enterprise Asset Management Systems). With its help, you can manage the maintenance of production and non-production assets, manage technological units and individual machines, but it can also be used to solve the maintenance of buildings and their parts. The maintenance management system can coordinate shutdowns with production plans within the MES and predict the time until the failure of production equipment. This contributes to an increased level of utilization of production assets with optimal maintenance costs and high reliability.

Operational data usage

The PATRIOT® 3.0 maintenance management system enables the automatic collection and evaluation of operational data of maintained equipment. It includes a SCADA system optionally supplemented with diagnostics even for dislocated sites.

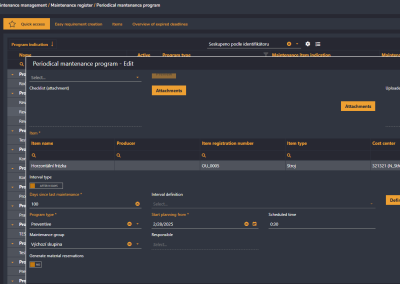

Optimization of maintenance schedule

A very useful feature is the optimization of the periodic preventive maintenance schedule. This plan is generated automatically according to limit conditions; the key is the possibility of manual “fine-tuning” according to the actual needs of the available resources.

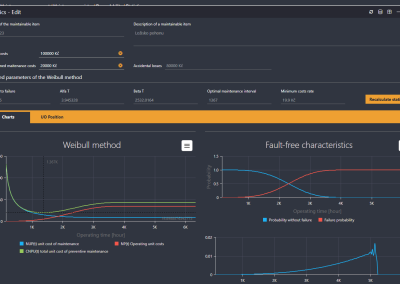

Analytical and statistical methods

The predictive maintenance module contains a statistical calculation method based on Weibull analysis. The maintenance management system will calculate the parameters.

CRYSTAL for maintenance management

A number of operators are now starting to take a deeper look at asset management or are still using a record-keeping system for maintenance or want to try out modern maintenance management in a pilot project. The CRYSTAL edition is dedicated to them.

More than 20 years of experience

The development of the maintenance management system began at dataPartner as early as 2001. Since 2005, dataPartner became a collective member of the Czech Society for Maintenance (CSM) which significantly influenced the development of the system and the resulting product included the requirements of maintenance standards.

Corrective maintenance

This is maintenance after a failure. The goal is to quickly eliminate the failure so that the object can perform the required function. Corrective maintenance is remedial, it reacts to the failure or malfunction that has occurred, and is therefore resolved only afterwards. It includes solving accidents and repairing reported failures.

Preventive maintenance

This is post-failure maintenance. The aim is to quickly remove the fault so that the object can perform the required function. Corrective maintenance is remedial, responding to the fault or failure that has occurred, so it is dealt with after the fact. It includes addressing the breakdown and repairing reported failures.

An optional add-on module is available in the Patriot® 3.0 Maintenance Management Information System.

Diagnostic maintenance

This is preventive maintenance according to technical condition, based on data obtained by monitoring performance and/or parameters.

Operational data usage:

The PATRIOT® 3.0 maintenance management system enables the automatic collection and evaluation of operational data of maintained equipment. It includes a SCADA system optionally supplemented with diagnostics even for dislocated sites. Most often, information from production control systems can be used directly for this purpose and if data is not available standard sensing units can be connected. The sensed operational data is stored in a database where it is used for analytical methods of time-to-malfunction calculations in predictive maintenance.

Predictive maintenance

It is carried out on the basis of a prediction derived from the analysis and evaluation of significant parameters that describe the level of degradation of an object.

Analytical and statistical methods:

The predictive maintenance module includes a statistical calculation method based on Weibull analysis. The maintenance management system will calculate the parameters of the Weibull probability distribution and the algorithm will calculate the optimal interval for timely maintenance before malfunction occurs.

Our customers

Thanks to our systems and solutions, we have gained the trust of major companies that rely on us to increase the efficiency and reliability of their operations. Join our satisfied customers.

Since 1996, the Swiss company Taconova Group AG has operated its main European production plant in Velešín, South Bohemia. It specializes...

Hunter Douglas Kadaň is part of an international corporation headquartered in the Netherlands, operating in over 100 countries worldwide....

Daikin Industries Czech Republic, located in Plzeň, has been utilizing the PATRIOT® CMMS maintenance management information system since...

Are you interested in our products?

Let’s meet.

We enjoy communicating, designing, solving, innovating, being open, and “building bridges on solid foundations.”