The Patriot® 3.0 maintenance management information system belongs to the group of systems known as CMMS (Computerized Maintenance Management Systems) or EAMS (Enterprise Asset Management Systems). With its help comes an endless possibility to manage the maintenance of both production and non-production assets, technological units and individual machines. The system can also be used to manage the maintenance of buildings and their parts. Within the MES, the maintenance management system can coordinate downtime with production schedules and predict the time of failure of production equipment. This contributes to increased utilisation of production assets at optimum maintenance costs and high reliability.

It minimizes the number of unplanned downtimes and thus increases the reliability of production, can significantly extend the service lifespan of production equipment and thus increase the economy of production. It optimises the deadlines for the execution of planned maintenance tasks contributing to the reduction of operating costs. This contributes to higher utilisation of production assets at optimum maintenance costs and to maintaining high reliability.

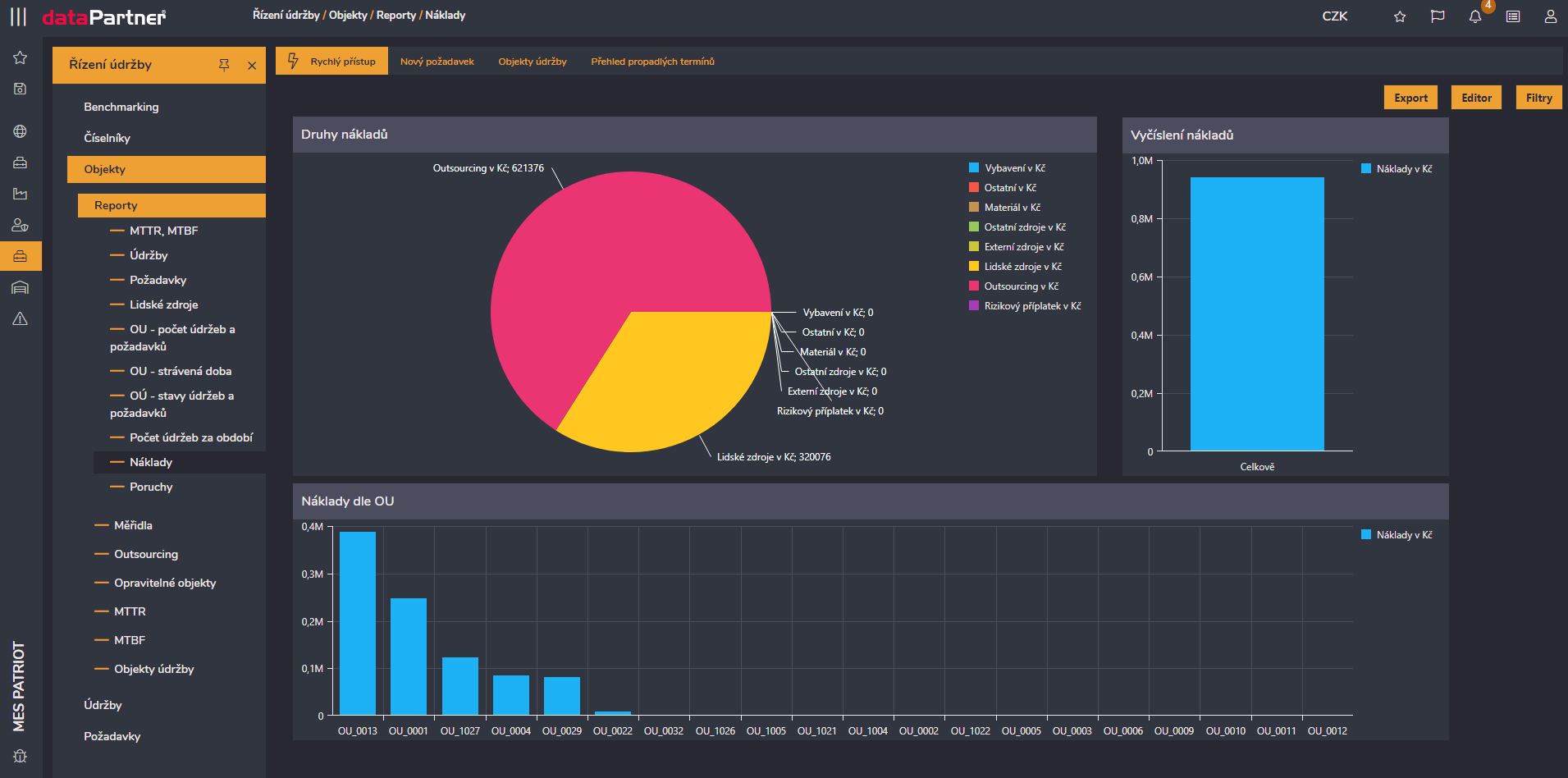

Reports on maintenance activities are also a very viable tool. The reports can quickly and clearly evaluate the current state of maintenance from multiple perspectives; the frequency of failures in individual equipment or production units based on historical and current data. Reports can be selected from a set of proven and frequently required reports or can be individually prepared. Virtually every report provides the option to customize and save filters that allow further customization of the view of the required data.

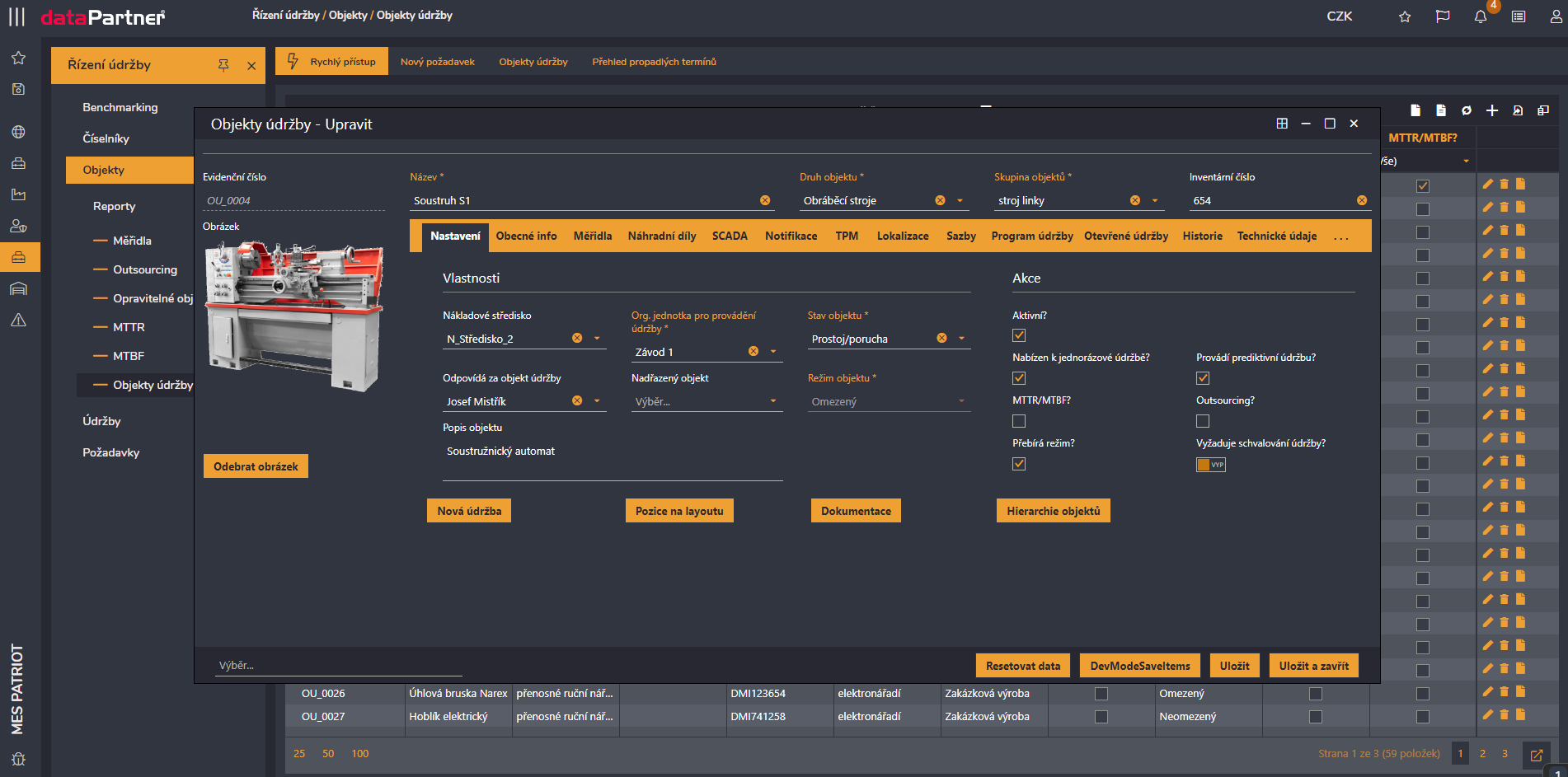

Correct terminology and an ergonomic and intuitive user interface play a very important role. The terminology is in line with EN 13306 (010660) ed. 2: Maintenance - Maintenance Terminology which unifies terms and facilitates communication across the maintenance and asset management community. The ergonomic and intuitive user interface is designed in a unified spirit and allows for easy and intuitive operation at the level from the maintenance terminal screens to the planning forms. The user interfaces also include mobile devices, smartphones and tablets which provide a working environment consistent with the entire system. This fact significantly contributes to the ease of implementation of PATRIOT® 3.0 by end customers and its smooth acceptance by all employees.

The PATRIOT® 3.0 maintenance management system enables the automatic collection and evaluation of operational data of maintained equipment. It includes a SCADA system, optionally supplemented with diagnostics; more here.

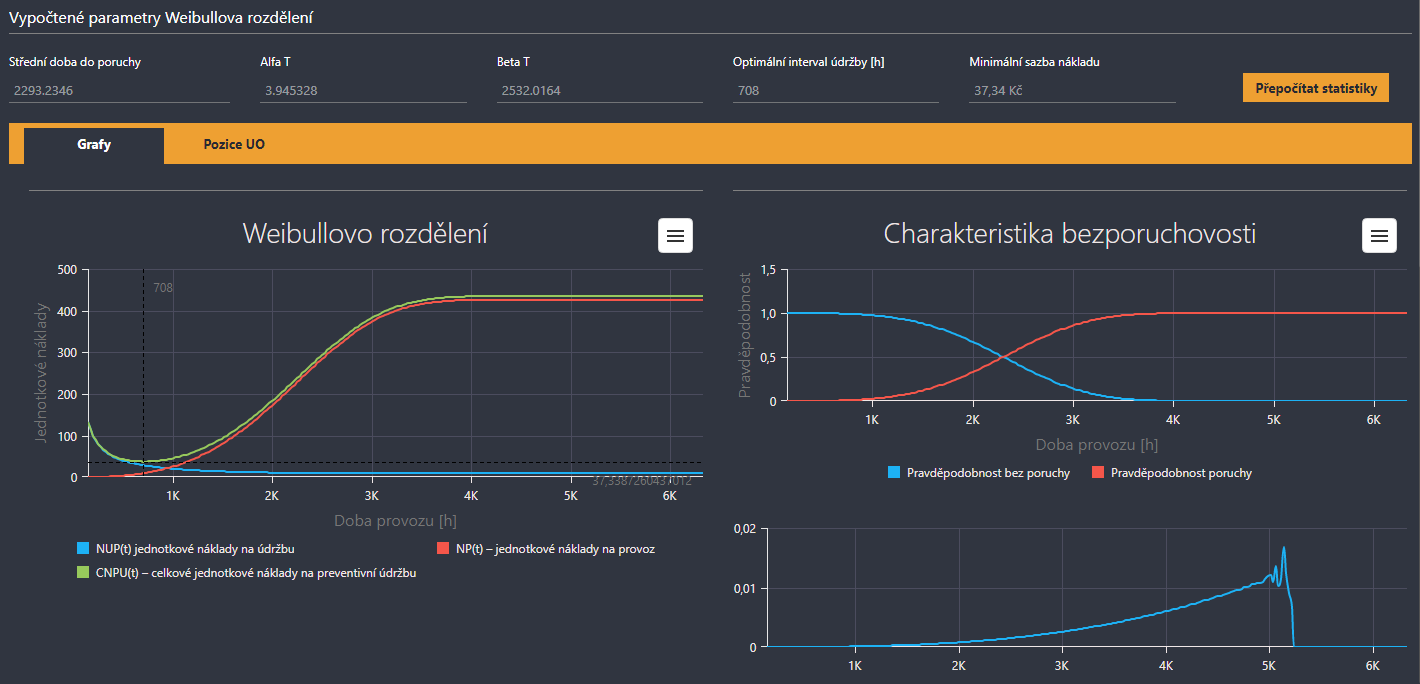

A very useful feature is the optimization of the periodic preventive maintenance schedule. More here.

The predictive maintenance module contains a statistical calculation method based on Weibull analysis. The maintenance management system performs the calculation of the parameters; more here.

A number of operators are now starting to take a deeper look at asset management or are still using a record-keeping system for maintenance or want to try out modern maintenance management in a pilot project. The CRYSTAL edition is dedicated to them.

The development of the maintenance management system began at dataPartner as early as 2001. Since 2005, dataPartner became a collective member of the Czech Society for Maintenance (CSM) which significantly influenced the development of the system and the resulting product included the requirements of maintenance standards. In 2016 the original PATRIOT maintenance management system was transferred to the subsidiary NUMERICA. As it had been on the market for more than 15 years at that time, it was a mature product however the concept was outdated and needed to be redesigned. In NUMERICA, a modern information system using new IT technologies was created with the cooperation of software developers, maintenance specialists from the Czech Agricultural University in Prague and the Czech Society for Maintenance. The newly developed framework also provides a platform for implementing other functionalities of production information systems of the MES category.

![]()

We are keen to communicate, to design, innovate and seek solutions. Straightforward in our deal-ings, we "build bridges on sound foundations".