Neutron Instrumentation and Reactor Protection System

Neutron Instrumentation

Reactor protection systems (RPS)

Neutron Instrumentation

Reactor protection systems (RPS)

Neutron Instrumentation

Here you can download leaflet to NEUTRON FLUX INSTRUMENTATION AND REACTOR PROTECTION SYSTEM.

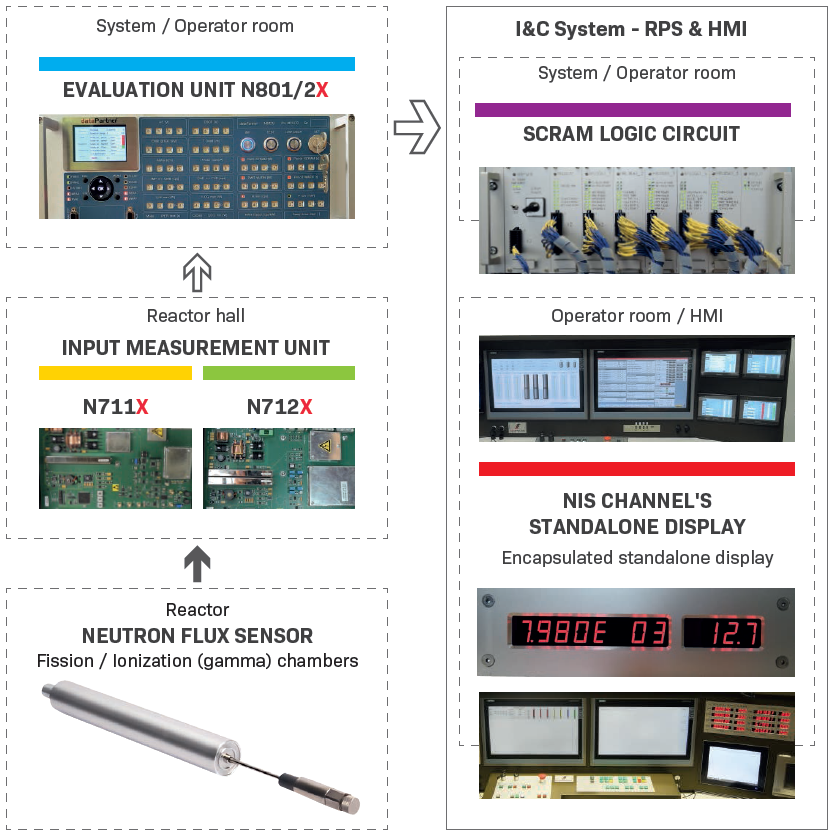

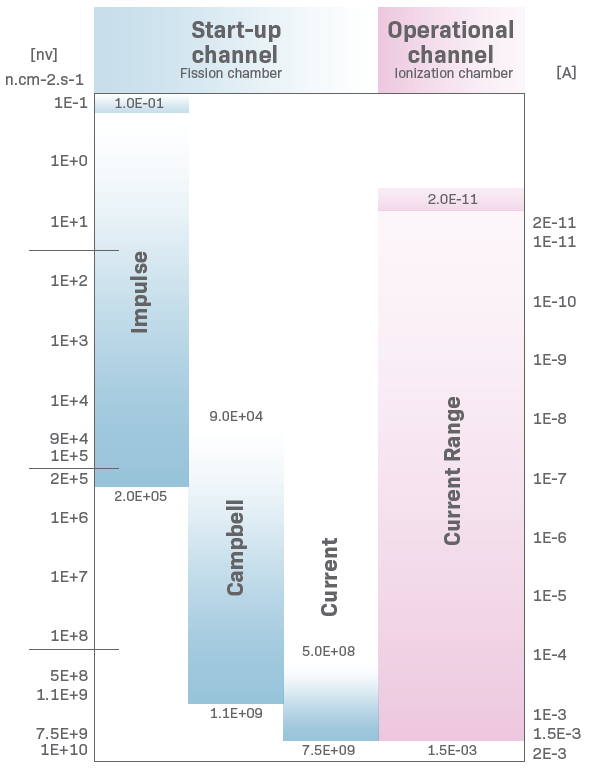

The ex-core neutron instrumentation operates as an autonomous independent system for safe control of the fission reaction in a nuclear reactor. The entire range of neutron flux measurement is covered by two types of measurement channels, to whose inputs signals from neutron flux sensors are connected:

Start-up Channel processes signals from the fission chamber in pulse mode starting from 1.0E-01 imp/s, continuing from 9.0E+04 imp/s in Campbell mode, and from 5.0E+8 imp/s it is able to operate in current mode.

Operating Channel processes the signal from the ionization chamber in the current mode in full accuracy with a range of 250nV @ 1E-10 A up to 3.75E+9nv @ 1.5E-3 A.

The length of the neutron flux sensors connection to the measurement unit can be up to 300 m, so the electronics are located out of reach of ionizing radiation. The output from the Measurement unit enters the Evaluation unit, to which SCRAM emergency protection chain unit and the Standalone display unit are connected for direct information to the operator about the values of the neutron flux and the reactor period.

The entire measurement channel for the neutron flux measurement system consists of:

- Neutron flux detector

- Measurement unit with integrated high voltage source for powering the detector

- Evaluation unit

- NIS Channel’s Standalone Display

Measurement unit

Evaluation unit

Standalone display

Measuring unit

Evaluation unit

Individual display

Measurement unit

is part of every channel.

Start-up channel contains a measuring unit that processes signal from impulse chamber by two methods:

- Using impulse counter, from which the signal is fed to 2 discriminators with adjustable discrimination level, which convert it into digital pulses. Their frequency per 10 ms is counted by an integrated microprocessor and sent optically for further processing.

- Using Campbell’s measurement of neutron flux as effective value of the signal obtained by filtering part of the input signal spectrum with a bandpass filter. The obtained signal is converted to DC and its effective value is converted into digital form. It is sent optically, together with other data, to the superior system for evaluation.

Operational channel contains a measuring unit that performs direct signal measurement from compensated current ionization chambers. The measured current from the chamber is fed to a logarithmic element in the unit and then converted into digital form by an AD converter. The converter uses sigma-delta technology, the conversion period is exactly 10 ms. A test current source is built into the unit and it can be used to test the correct function of the entire measuring chain at any time. The unit communicates with the superior evaluation and control unit via an optical link.

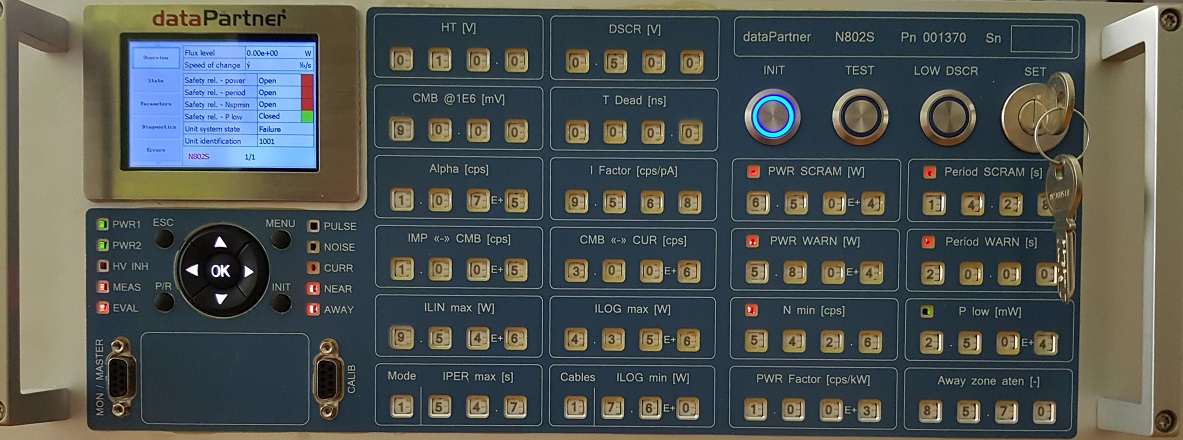

Evaluation unit

Evaluation unit performs the reactor protection functions by evaluating data from the measurement unit. For this reason, it is classified in the highest safety class A, so it only performs functions related to nuclear safety. The unit has the following key features:

- Measurement evaluation cycle 10 ms (synchronously with the measuring unit).

- SCRAM outputs: Power, Period, NMIN.

- BLOCK outputs for safe blocking of other devices that report an NMIN error at low neutron flux.

- 16 separate relay outputs to signal basic results and conditions, 3 of them are programmable.

- 2×3 analog outputs 4÷20 mA for exporting measured values (PWRLOG, PWRLIN, PERIOD).

- Safety logic inputs for monitoring the working positions of the neutron chamber.

- Fully redundant and galvanically isolated power supply from two 24VDC branches.

- Complete, safe, clear, easily accessible, authorized and very simple setup of all necessary parameters for neutron flux measurement and evaluation.

The evaluation unit provides the output signal to an standalone display for the reactor control system and further to an independent monitoring system and to an external HMI. The communication protocols are modifiable and work independently of the unit safety functions.

The front panel of the evaluation unit is equipped with a display that provides a complete overview of the measurement results and the internal states of the evaluation and measurement unit. The main part of the panel is occupied by adjustable dials, which serve for safe, clear, authorized and simple setting of all apparatus parameters. The control buttons and SET lock authorization serve for initialization, testing and execution of authorized settings and also serve as indicators. The CALIB connector allows for an external calibrator connection to the internal calibrator. It is used for testing and calibrating output current loops 4÷20mA.

Standalone Display

Standalone Display is an autonomous device with a combined character display for displaying neutron flux values and neutron flux rate change(reactor period). The display consists of 12 segments divided into two groups: The first 8 segments display the neutron flux value, the second group of 4 segments displays the change of reactor period rate.

Reactor Protection systems (RPS)

SCRAM LOGIC CIRCUIT unit forms an emergency chain that ensures the safety function of the nuclear reactor protection system. It is classified in the highest safety class, performs category A functions according to ČSN EN IEC 61226 and therefore is implemented as a relay system with a redundant arrangement. It receives signals from the neutron flux measurement and evaluation units and from the reactor measurement and control system. In the event that a value exceeds the safety limit or an instrumentation failure occurs, it immediately disconnects the power supply to the control rods electromagnets, causing the rod fall by gravity into the core and thus the quick reactor shut down. The SCRAM chain is set up so that any possible failure in the device is safe because it leads to a safe shutdown of the reactor.

3 types of modules are used to configure RPS system units:

- HRPWR – Power supply modules

- HRLOG – Relay logic modules

- HROUT – Output modules

Are you interested in our services?

Let’s meet.

We enjoy communicating, designing, solving, innovating, being open, and “building bridges on solid foundations.”